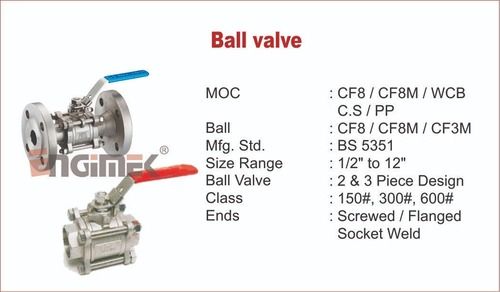

Manual Ball Valve

Manual Ball Valve Specification

- Valve Size

- 1/2 to 4

- Features

- Corrosion Resistant, Leak Proof, Compact Design

- Material

- Brass / Stainless Steel / MS

- Control System

- Handle Lever

- Valve Type

- Manual Ball Valve

- Connection Type

- Screwed / Flanged / Socket Weld

- Sealing

- PTFE/Gasket

- Application

- Water, Oil, Gas, Chemical Industries

- Structure

- Two Piece

- Type

- Ball Valve

- Power

- Manual

- Pressure

- PN16 / 150 PSI

- Media

- Water, Air, Oil, Gases

- Port Size

- 15mm to 100mm

- Temperature

- -20C to 180C

- Disc

- SS / Brass

- Pin

- Single/Double Pin Option

- Operation

- Quarter Turn

- Handle Material

- Mild Steel with PVC Cover

- Design Standard

- IS / DIN / ANSI

- Ball Material

- Stainless Steel / Chrome Plated Brass

- End Connection

- Threaded (BSP/NPT), Flange

- Body Finish

- Nickel / Chrome / Polyurethane Coated

- Weight

- Varies with size (0.3kg3.2kg approx.)

- Packing

- Box / Carton

Manual Ball Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Manual Ball Valve

A type of valve used to regulate the flow of a fluid (liquid or gas) through a pipeline is a manual ball valve. It consists of a sphere with a hole running through the middle of it. When the valve is open, the ball's bore lines up with the pipeline, enabling fluid to travel through. Closed valves cause the ball to spin 90 degrees, aligning the bore perpendicular to the pipeline, and blocking flow. Turning a lever or handle that is attached to the ball opens and closes the valve manually.

Benefits:

- The Manual Ball Valve has a strong construction that guarantees its long-term dependability and durability in a variety of applications. The valve provides smooth and simple manual operation with its ergonomically designed handle, minimizing human effort and guaranteeing accurate control.

- The valve has a leak-proof design that stops any unintentional fluid leaking, improving safety and reducing waste.

- The full bore design of the valve minimizes pressure drop and ensures effective fluid transfer through the valve by allowing for unhindered flow.

- The valve, which is made of corrosion-resistant materials and suitable for use with a range of liquids and gases, keeps working even in challenging settings.

Manual Ball Valve is a hand worked liquid stream control gadget which is fixed with a focal quarterly turn steel ball which pivots as the switch turns to open or close the stream divert which thus brings about change in stream rate however the pipelines. Hardened steel is utilized for the creation of this rock solid part which gives more prominent strength and durability to oppose huge effect power and tension. This valve presented by our organization can be altered in various sizes according to client requests.

Manual Ball Valve Applications:

FAQ:

1. What is a manual ball valve?

2. How does a manual ball valve function?

3. What are the fundamental parts of a manual ball valve?

4. What are the benefits of utilizing manual ball valves?

5. In what applications are manual ball valves normally utilized?

6. Might manual ball valves at any point give choking or stream control?

7. What kinds of liquids can be controlled with manual ball valves?

8. What are the restrictions of manual ball valves?

9. How would I pick the perfect manual ball valve for my application?

10. How would I keep up with manual ball valves?

11. Might manual ball valves at any point be computerized?

12. What is the distinction between a full-port and a decreased port ball valve?

Versatile End Connections for Easy Integration

Choose from threaded (BSP/NPT), flanged, or socket weld end connections to fit your specific pipeline requirements. This flexibility allows straightforward integration into existing systems, minimizing downtime during installation and maintenance, and ensuring a reliable seal for various applications.

Robust Construction and Superior Finishing

Manufactured using stainless steel, chrome plated brass, or mild steel, these valves are finished with robust coatings such as nickel, chrome, or polyurethane. This multi-layer protection safeguards the valve against corrosion, wear, and chemical attack, prolonging service life in demanding industrial environments.

User-Friendly Operation and Reliable Sealing

The quarter-turn handle lever-crafted from mild steel and covered in PVC for comfort-enables smooth, swift operation. Paired with PTFE or gasket sealing, this design delivers excellent leak-proof performance and efficient flow control, making it ideal for industries where reliability is essential.

FAQ's of Manual Ball Valve:

Q: How should the Manual Ball Valve be installed for optimal performance?

A: To ensure optimal performance, select an appropriate end connection-threaded (BSP/NPT), flanged, or socket weld-based on your pipeline system. Properly align the valve and ensure all connections are secure and sealed. Follow the relevant design standards (IS, DIN, ANSI) and utilize PTFE or gasket sealing to prevent leaks.Q: What types of media are compatible with this valve?

A: This manual ball valve is designed for versatility and can be used with water, air, oil, and various gases. Its corrosion-resistant construction also makes it suitable for handling chemicals and other industrial fluids within the specified temperature and pressure ranges.Q: Where can these ball valves be effectively applied?

A: These valves are ideal for use in water supply systems, oil and gas pipelines, chemical processing industries, and general industrial applications. Their corrosion resistance and leak-proof features make them suitable for both indoor and outdoor installations across diverse sectors.Q: What is the benefit of the quarter-turn operation of this valve?

A: The quarter-turn operation allows for fast, effortless opening and closing of the valve, improving flow control and minimizing manual effort. This feature is especially beneficial in applications that require frequent operation or emergency shut-off.Q: What process should be followed for regular maintenance of the valve?

A: Regular maintenance involves inspecting for external leaks, verifying tightness of the end connections, and testing the handle operation. Periodically check the valve for signs of corrosion or wear, and replace PTFE/gasket seals if necessary to maintain leak-proof performance.Q: When is it advisable to use the single or double pin option?

A: The choice between single and double pin options depends on application requirements-double pin configurations offer added stability and security in high-pressure or critical uses, while single pin is suitable for standard applications where easy operation suffices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Manual Valve Category

Knife Edge Gate Valve

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Pulp & Paper, Chemical, Mining, Food & Beverage, Water Treatment, Power Plants, Slurry Handling, Sugar Industries

Structure : Other, Single Piece Body, Unidirectional or Bidirectional as per requirement

Media : Other, Slurry, Liquids with Suspended Solids, Pulpy Media, Viscous Fluids

Pressure : Other, Up to 10 bar (PN10), Higher rating on request

Manual Knife Edge Gate Valve

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial flow control, wastewater treatment, pulp and paper, chemical processing, mining, food and beverage, and bulk handling systems.

Structure : Other, Knife Edge Gate Valve

Media : Other, Slurry, Liquids, Semisolids, Powders, Pulps

Pressure : Other, Up to 16 bar (232 psi)

Manual Double Flange Butterfly Valve

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Water supply, wastewater, HVAC, irrigation, and industrial pipelines.

Structure : Other, Double Flange

Media : Other, Water, air, gas, oil, and other compatible fluids

Pressure : Other, PN10/PN16/PN25 (customizable)

Manual Disc Check Valve

Price 10000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Application : industrial

Structure : Check

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free