Manual Double Flange Butterfly Valve

Price 3000 INR/ Piece

Manual Double Flange Butterfly Valve Specification

- Features

- Bi-directional tightness, low operating torque, maintenance-free, corrosion resistance

- Valve Size

- DN50 to DN1200

- Valve Type

- Manual Double Flange Butterfly Valve

- Connection Type

- Double flange connection

- Control System

- Manual lever/gear operation

- Material

- Body: Cast Iron / Ductile Iron, Disc: Ductile Iron / SS, Stem: Stainless Steel

- Sealing

- EPDM, NBR, PTFE (dependent on specification)

- Application

- Water supply, wastewater, HVAC, irrigation, and industrial pipelines.

- Structure

- Double Flange

- Type

- Butterfly Valve

- Power

- Manual operated

- Pressure

- PN10/PN16/PN25 (customizable)

- Media

- Port Size

- DN50 to DN1200 (2 - 48)

- Temperature

- -20C to 120C (dependent on seat material)

- Disc

- Ductile iron/Nickel plated/SS 304/SS 316

- Pin

- Stainless steel or carbon steel

- Leakage Class

- Zero leakage (bubble tight)

- Color

- Blue (Standard), others available upon request

- Face to Face Length

- Complies with ISO 5752 Series 13/14

- Mounting Position

- Suitable for any position (horizontal or vertical)

- Coating

- Epoxy powder coated, 250m minimum

- Stem Design

- Anti-blowout stem

- Handle/Actuator

- Cast iron/Aluminum hand lever or gear box

- Packing

- Sea-worthy plywood cases

- End Connection Standard

- EN1092, ANSI, JIS available

- Operation

- Quarter turn (90 rotation)

- Top Flange Drilling

- ISO 5211 mounting

- Environment Suitability

- Indoor and outdoor applications

- Seat Material

- EPDM, NBR, or PTFE as per application

Manual Double Flange Butterfly Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Manual Double Flange Butterfly Valve

Manual Twofold Rib Butterfly Valve Determinations:

FAQ:

Q1: What is a Manual Twofold Rib Butterfly Valve?

Q2: How does a Manual Twofold Rib Butterfly Valve work?

Q3: Where are Manual Twofold Rib Butterfly Valves utilized?

Q4: What are the upsides of utilizing Manual Twofold Spine Butterfly Valves?

- Fast quarter-turn activity.

- Smaller plan and lightweight development.

- Low-pressure drop across the valve.

- Savvy contrasted with other valve types.

- Reasonable for enormous width pipelines.

- Simple support and establishment.

Q5: Are there any restrictions to utilizing these valves?

- Not appropriate for applications requiring exact choking or tight shut-off.

- The plate can amass flotsam and jetsam over the long run, influencing execution.

- Fixing materials might break down quicker in grating or destructive conditions.

Q6: How would I pick the right size for my application?

Q7: What materials are these valves normally produced using?

Q8: Could Manual Twofold Spine at any point Butterfly Valves be mechanized?

Q9: How would I introduce and keep up with these valves?

Q10: Where could I at any point purchase Manual Twofold Spine Butterfly Valves?

Superior Performance and Flexibility

Engineered for reliability, the Manual Double Flange Butterfly Valve provides zero leakage and bi-directional tightness. It operates efficiently with low torque, thanks to its anti-blowout stem and precision disc design. This valve suits a wide range of environments and application types, including water, air, oil, and compatible fluids, maintaining top performance under varied pressure and temperature conditions.

Versatile Application and Easy Installation

Conforming to ISO and international end connection standards, the valve can be installed horizontally or vertically in pipelines, ensuring adaptability for distributors, exporters, manufacturers, and suppliers across sectors. Its double flange connection allows for secure and quick mounting, while the mounting flange complies with ISO 5211 for actuator compatibility.

Corrosion Resistance and Durability

With an epoxy powder coating of at least 250m, the valve offers excellent protection against corrosion and harsh environments. Suitable for both indoor and outdoor setups, it promises lasting durability. All components, from the cast iron body to the stainless steel or carbon steel pins, are designed for long-term use and minimal maintenance.

FAQ's of Manual Double Flange Butterfly Valve:

Q: How does the manual double flange butterfly valve operate?

A: The valve uses a quarter-turn (90 rotation) mechanism via a hand lever or gear box, providing fast and precise control for opening or closing. Operation is simple and does not require additional power sources.Q: What types of fluids and environments can this valve handle?

A: It is suitable for water, air, gas, oil, and other compatible fluids, and designed for indoor or outdoor use in applications such as water supply, wastewater, HVAC, irrigation, and industrial pipelines.Q: When is it beneficial to choose EPDM, NBR, or PTFE seat material?

A: Choose EPDM for water and general applications, NBR for oil and gases, and PTFE for aggressive chemicals or higher temperature environments. Selection depends on your specific media and operational requirements.Q: Where can this valve be installed within a pipeline system?

A: Thanks to its double flange connection and versatile mounting position, the valve can be installed horizontally or vertically in a wide range of locations, accommodating different pipeline layouts and requirements.Q: What standards does the valve comply with for installation and connection?

A: It meets ISO 5752 Series 13/14 for face-to-face length, ISO 5211 for top flange mounting, and offers end connection compatibility with EN1092, ANSI, and JIS standards for global adaptability.Q: How does the valve ensure zero leakage and safe operation?

A: Featuring bi-directional bubble-tight sealing and an anti-blowout stem design, the valve ensures no leakage and safe operation even under high pressure conditions, making it dependable for critical pipeline networks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Manual Valve Category

Manual Gate Valve

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Water, Oil, Gas, Steam

Structure : Other, Rising Stem

Pressure : Other, Up to 16 bar

Knife Edge Gate Valve

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Slurry, Liquids with Suspended Solids, Pulpy Media, Viscous Fluids

Structure : Other, Single Piece Body, Unidirectional or Bidirectional as per requirement

Pressure : Other, Up to 10 bar (PN10), Higher rating on request

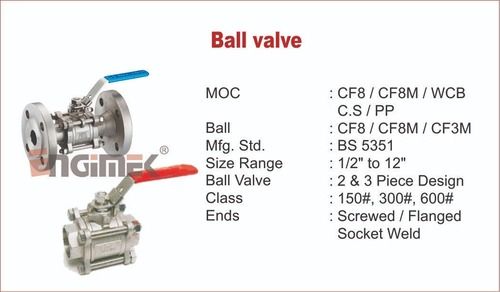

Manual Ball Valve

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Water, Air, Oil, Gases

Structure : Other, Two Piece

Pressure : Other, PN16 / 150 PSI

Manual Butterfly Valve

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Water

Structure : Butterfly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free