Manual Knife Edge Gate Valve

Price 8000 INR/ Piece

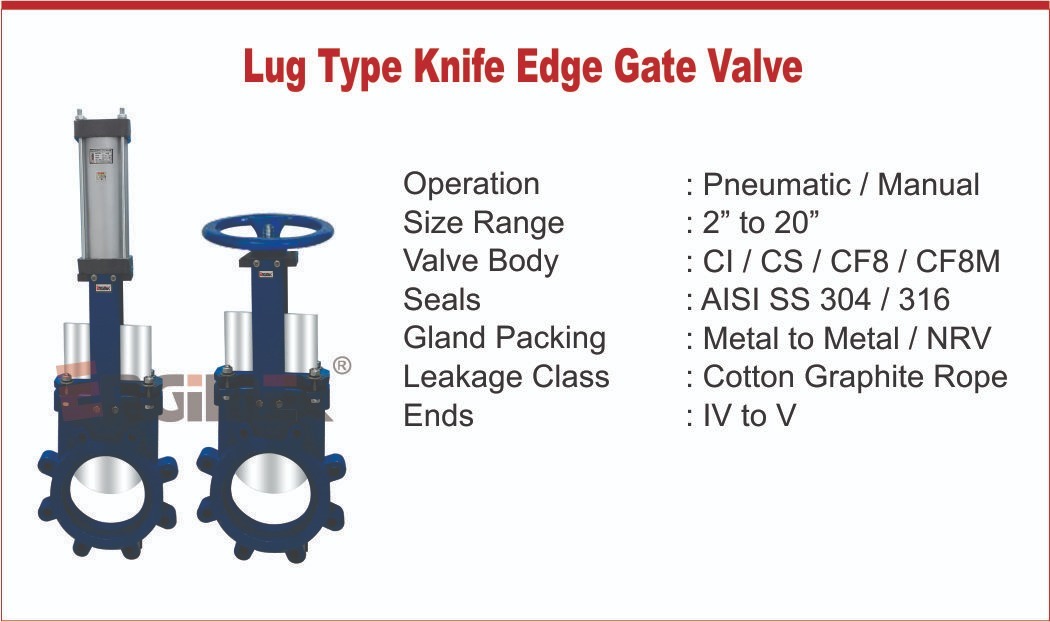

Manual Knife Edge Gate Valve Specification

- Valve Size

- 2 to 24 (DN50 - DN600)

- Connection Type

- Flanged / Wafer / Lug / Butt Weld Ends

- Control System

- Manual Handwheel or Lever Operated

- Features

- Rugged construction, easy maintenance, bidirectional sealing, compact design

- Valve Type

- Manual Knife Edge Gate Valve

- Material

- Body: Cast Iron/ Ductile Iron/ Stainless Steel / Carbon Steel; Trim: Stainless Steel

- Application

- Industrial flow control, wastewater treatment, pulp and paper, chemical processing, mining, food and beverage, and bulk handling systems.

- Structure

- Knife Edge Gate Valve

- Sealing

- Rubber, PTFE, or Metal seated options

- Voltage

- N/A (Manual Operation)

- Type

- Gate Valve, Knife Edge Type

- Power

- Manual

- Pressure

- Up to 16 bar (232 psi)

- Media

- Slurry, Liquids, Semi-solids, Powders, Pulps

- Port Size

- 2 inch to 24 inch (DN50 - DN600)

- Temperature

- -20C to 180C depending on sealing and material selection

- Disc

- Stainless Steel / Cast Iron / Alloy Steel (as per model)

- Pin

- Stainless steel

- Operation

- Quarter turn/Linear handwheel operation

- Testing Standard

- 100% factory tested as per API 598/BS 5154

- Packing

- High quality gland packing for zero leakage

- Design Standard

- Manufactured as per MSS SP 81

- Actuator Compatibility

- Convertible for pneumatic or electric actuator

- End Connection Standard

- Conforms to ASME, DIN, BS, or IS standards

- Body Coating

- Epoxy coated for corrosion resistance

- Gasket

- PTFE or Graphite (as per requirement)

- Stem Type

- Rising or non-rising stem options

Manual Knife Edge Gate Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Manual Knife Edge Gate Valve

Applications:

- A robust and long-lasting design distinguishes the Manual Knife Edge Gate Valve, assuring dependable performance even in demanding industrial applications.

- This valve's ability to precisely control flow enables for exact modification of the flow rates of materials or fluids, increasing operational effectiveness.

- The valve offers a tight and secure shut-off, limiting leakage and preventing material accumulation, thanks to its distinctive knife-edge gate.

- The valve's simple manual operating mechanism enables operators to quickly open or close the gate as needed and promotes seamless control.

- This valve delivers remarkable longevity by withstanding hostile conditions and corrosive chemicals since it is made of corrosion-resistant materials.

Reliable Flow Control for Demanding Applications

The Manual Knife Edge Gate Valve stands out in sectors like wastewater treatment, chemical processing, mining, and more. Its rugged construction supports consistent performance despite challenging conditions. With sizes ranging from DN50 to DN600, and various end connections conforming to leading standards, it offers extensive compatibility for industrial systems.

Engineered for Durability and Leak-Free Operation

Equipped with epoxy coating for superior corrosion resistance and high-quality gland packing, these valves ensure zero leakage. The optional PTFE, graphite, or metal seats, along with robust stem and disc materials, further extend service life and enable the valve to withstand temperatures from -20C to 180C and pressures up to 16 bar.

Flexible Design and Easy Maintenance

Choose between rising or non-rising stem models, flanged, wafer, lug, or butt weld end connections, and a selection of seats based on your requirements. The compact build and straightforward manual operation simplify installation and routine maintenance. Future upgrades, such as pneumatic or electric actuators, can be easily implemented.

FAQ's of Manual Knife Edge Gate Valve:

Q: How does the operation of the Manual Knife Edge Gate Valve work?

A: This valve is operated manually using either a handwheel or lever. Depending on the selected model, operation is either quarter-turn or linear, which moves the gate up or down to control flow through the pipeline.Q: What makes the valve suitable for corrosive or harsh environments?

A: The body is epoxy coated for enhanced corrosion resistance, and high-quality gland packing and seat material options like PTFE or graphite help ensure longevity even under aggressive conditions.Q: When should I choose a rising stem over a non-rising stem design?

A: A rising stem model is suitable when it is important to visually verify valve position, while non-rising stems are ideal for installations with vertical space constraints or where external stem exposure needs to be minimized.Q: Where can Manual Knife Edge Gate Valves be applied effectively?

A: These valves are widely used in wastewater treatment, chemical processing, pulp and paper manufacturing, mining, food and beverage processing, and bulk handling systems involving slurries or semi-solids.Q: What is the process for selecting the right gasket and seat material?

A: Gasket and seat material selection depends on the flowing medium and temperature requirements. PTFE is suitable for most chemicals and higher temperatures, graphite is used for higher temperature applications, while rubber and metal options are chosen based on the type of media and pressure involved.Q: How can the valve be adapted for automated control in the future?

A: The valve is designed to be convertible to pneumatic or electric actuator operation, enabling seamless integration with automated control systems without replacing the main valve body.Q: What are the benefits of choosing this valve for my facility?

A: Key benefits include rugged construction for reliability, zero leakage due to quality packing, easy maintenance, compatibility with multiple standards (ASME, DIN, BS, IS), and the ability to handle a wide range of media under harsh conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Manual Valve Category

Knife Edge Gate Valve

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Slurry, Liquids with Suspended Solids, Pulpy Media, Viscous Fluids

Structure : Other, Single Piece Body, Unidirectional or Bidirectional as per requirement

Pressure : Other, Up to 10 bar (PN10), Higher rating on request

Manual Gate Valve

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Water, Oil, Gas, Steam

Structure : Other, Rising Stem

Pressure : Other, Up to 16 bar

Manual Universal NRV

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Water, Oil, Gas, Chemical

Structure : Other, Nonreturn valve

Pressure : Other, 10 Bar

Manual Butterfly Valve

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Water

Structure : Butterfly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free