Manual Off Set Disc Butterfly Valve

Manual Off Set Disc Butterfly Valve Specification

- Valve Type

- Double Offset Butterfly Valve

- Connection Type

- Flanged / Wafer / Lug Type

- Valve Size

- 2 to 48 (DN50 to DN1200)

- Material

- Cast Iron, WCB, SS304, SS316

- Features

- Low Operating Torque, Bi-directional Seal, Maintenance Free Design

- Control System

- Manual Gear Operated

- Application

- Water, Oil & Gas, Chemical Industries

- Structure

- Double Offset Disc

- Sealing

- EPDM / NBR / PTFE / Metal Seated

- Type

- Butterfly Valve

- Power

- Manual

- Pressure

- PN10, PN16, PN25, PN40

- Media

- Liquid, Gas, Air

- Port Size

- DN50 to DN1200

- Temperature

- -10C to 180C

- Disc

- Off Set Disc, SS304 / SS316 / Ductile Iron

- Pin

- Stainless Steel Pin

- Color

- Blue / Customized

- Shaft Bearing

- PTFE/ Bronze

- Coating

- Epoxy Powder Coated Exterior

- Operation

- Quarter Turn Operation

- Body Design

- One-piece or Split Body

- Face to Face Dimension

- EN 558 Series 13 & 14

- Weight

- Varies with size

- Leakage Class

- Class VI

- Top Flange Standard

- ISO 5211

- Mounting

- Direct actuator mounting possible

- Hydrostatic Test Pressure

- Up to 60 Bar

- Handle Type

- Lever / Gearbox

- End Connection Standard

- ANSI, DIN, BS

- Stem Material

- Stainless Steel

- Packing

- Standard Export Packing

- Suitable Flow Direction

- Bi-Directional

Manual Off Set Disc Butterfly Valve Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 1 Days

About Manual Off Set Disc Butterfly Valve

This Manual Off Set Disc Butterfly Valve is a crucial part for several industrial applications since it is built to deliver great performance and simplicity of use. Our Manual Off Set Disc Butterfly Valve, which was made with attention to detail and high-quality materials, is built solidly to assure longevity even in difficult settings. The offset disc design provides a tight seal, reducing leakage and increasing fluid flow management efficiency.

Benefits:

- With the Manual Off Set Disc Butterfly Valve, customers may precisely change the flow rate to satisfy certain process needs.

- This valve's manual control mechanism allows for quick opening and shutting, making it perfect for situations when a prompt shutoff is required.

- It is a manual valve, therefore there is no need for intricate automation systems, which lowers startup costs and maintenance costs.

- It is appropriate for installations with limited space because of its lightweight and compact design, which reduces the amount of space needed.

A Manual Offset Plate Butterfly Valve is a kind of modern valve utilized for controlling the progression of liquids (fluids or gases) inside a channeling framework. It falls under the class of quarter-turn valves and is intended to be worked physically, normally by turning a handwheel or switch.

Here is a breakdown of its critical parts and how it functions:

This is the way the valve works:

FAQ:

Q. What is a Manual Counterbalanced Circle Butterfly Valve?

Q. How does a Manual Balance Circle Butterfly Valve work?

Q. What are the benefits of utilizing an Offset Plate Butterfly Valve?

Q. Where are Manual Counterbalanced Circle Butterfly Valves utilized?

Q. How is the valve physically worked?

Q. What is the reason for the offset plan?

Q. Might Manual Counterbalance Circle at any point Butterfly Valves be mechanized?

Q. What upkeep is expected for these valves?

Q. How would I pick the right size of valve for my application?

Q. Could these valves at any point deal with the two fluids and gases?

Q. Are these valves appropriate for choking or only on/off control?

Q. What materials are these valves produced using?

Q. Are there any constraints to utilizing these valves?

Versatile and Robust Construction

Engineered with a choice of one-piece or split body and available in cast iron, WCB, SS304, or SS316, this butterfly valve offers rugged reliability in demanding environments. The double offset disc reduces wear and ensures a tight seal, making it ideal for various fluid control applications where durability and maintenance-free design are essential.

Efficient Operation and Mounting Options

Designed for manual control through a lever or gearbox, this valve supports direct actuator mounting-providing flexibility for future automation. The quarter turn operation allows swift flow adjustment, minimizing energy loss, and the top flange adheres to ISO 5211 standards for compatibility with a broad array of actuators and accessories.

Reliable Sealing and Customization

With options for EPDM, NBR, PTFE, or metal seating, and bearing materials like PTFE or bronze, this valve accommodates different process media and temperature ranges. The epoxy powder coated exterior offers superior corrosion resistance, while color and size can be customized based on project requirements. It's perfect for distribution, export, and industrial supply needs.

FAQ's of Manual Off Set Disc Butterfly Valve:

Q: How is the Manual Off Set Disc Butterfly Valve installed and where can it be used?

A: The valve is installed in piping systems using flanged, wafer, or lug-type connections that comply with ANSI, DIN, or BS standards. It is suitable for water, oil, gas, chemical, and power plant applications, making it ideal for industries seeking durable, versatile flow control solutions.Q: What is the benefit of the double offset disc design in this butterfly valve?

A: The double offset disc minimizes contact between the valve disc and seat during operation, reducing friction, improving sealing performance (Class VI leakage), and extending service life. This results in lower maintenance requirements and reliable sealing in bi-directional flow.Q: When should I choose EPDM, NBR, PTFE, or metal seated options for sealing?

A: Select sealing materials based on your process media and temperature. EPDM is suitable for water and mild chemicals, NBR for oil and hydrocarbons, PTFE offers excellent chemical resistance, and metal seats are ideal for high-temperature or abrasive applications operating between -10C and 180C.Q: How does the valve ensure corrosion resistance and long-term durability?

A: The valve body is epoxy powder coated externally, providing a robust barrier against environmental factors and corrosion. Coupled with stainless steel internals and weather-resistant bearing options, it is designed for maintenance-free, long-term operation in challenging environments.Q: What control and operation options are available for this butterfly valve?

A: The valve can be operated manually with a lever for quick adjustments or a gearbox for precise control. It also supports direct actuator mounting (ISO 5211 standard) for automation, offering flexibility based on the desired level of operation and control system.Q: What are the available sizes and pressure ratings for this valve?

A: This butterfly valve is available in port sizes ranging from DN50 to DN1200 (2 to 48 inches), with pressure ratings of PN10, PN16, PN25, and PN40. Its hydrostatic test pressure resistance is up to 60 bar, ensuring reliability in high-pressure systems.Q: Can the valve be customized for specific applications or project requirements?

A: Yes, the valve is available in customizable colors, materials (such as cast iron, WCB, SS304, or SS316), disc variants, and connection types. Packing is done to standard export specifications, and product configurations can be tailored to meet application or project-specific needs when ordered through a distributor or manufacturer in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Manual Valve Category

Manual Double Flange Butterfly Valve

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Other, Double Flange

Application : Water supply, wastewater, HVAC, irrigation, and industrial pipelines.

Media : Other, Water, air, gas, oil, and other compatible fluids

Manual Universal NRV

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Other, Nonreturn valve

Application : Industrial fluid flow control, piping systems, water supply, irrigation, chemical processing

Media : Other, Water, Oil, Gas, Chemical

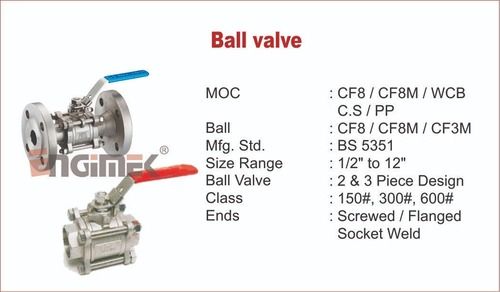

Manual Ball Valve

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Other, Two Piece

Application : Water, Oil, Gas, Chemical Industries

Media : Other, Water, Air, Oil, Gases

Manual Butterfly Valve

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Butterfly

Application : industrial

Media : Water

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free