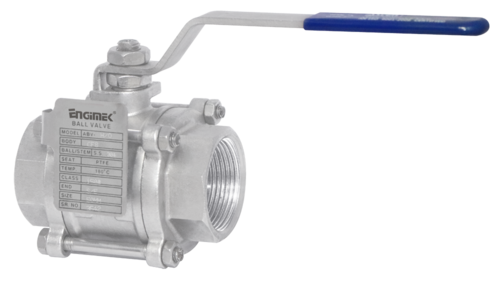

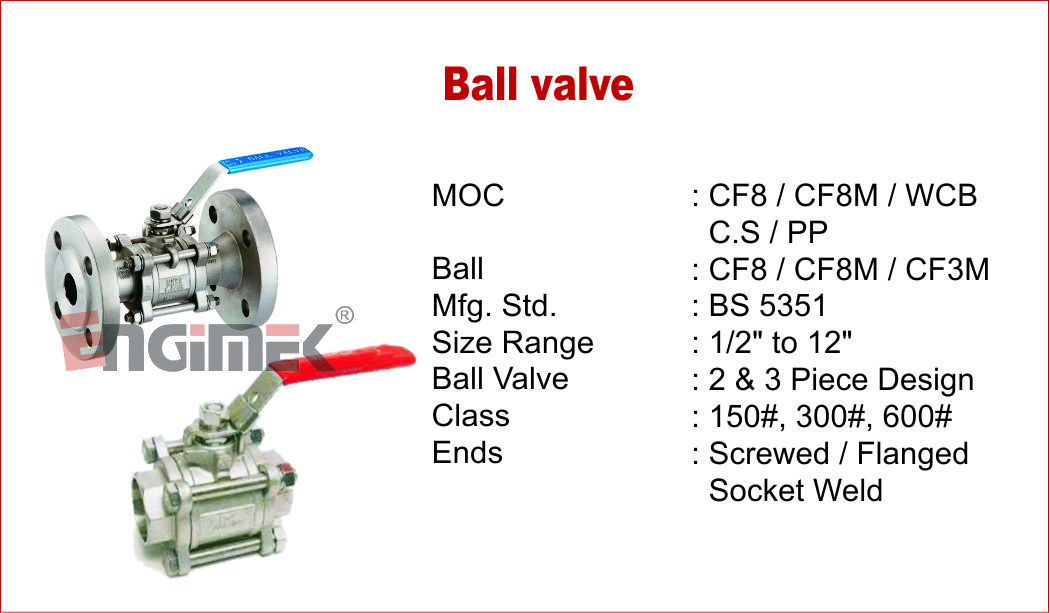

Three Piece Screwed End Ball Valve

Price 8000 INR/ Piece

MOQ : 01 Piece

Three Piece Screwed End Ball Valve Specification

- Caliber

- Standard Bore

- Structure

- Three Piece

- Channels

- Single Channel

- Pressure

- Up to PN63 / 1000 PSI

- Connection

- Screwed (BSP/NPT)

- Material

- Stainless Steel / CF8 / CF8M / WCB

- Power

- Manual

- Media

- Water, Oil, Gas, Acid, Steam

- Temperature of Media

- -20C to +200C

- Port Size

- 1/2 inch to 4 inch

- Flange

- No

- Finish

- Polished / Machined

- Application

- Industrial, Chemical, Petrochemical, Process, Water Treatment

- Body Test Pressure

- Hydrostatic at 1.5 times working pressure

- Antistatic Device

- Optional

- Mounting

- ISO 5211 Standard Optional

- Locking Arrangement

- Available

- Handle Material

- Stainless Steel with PVC Sleeve

- Blowout Proof Stem

- Yes

- Design Standard

- ASME B16.34 / API 608

- Fire Safe Design

- Optional

- Operation

- Quarter Turn

- Seat Material

- PTFE / Teflon

- End Connection Standard

- BSP / NPT (as per IS/ISO/DIN)

- Leakage Class

- Bubble Tight (Zero Leakage)

- Ball Test Pressure

- Hydrostatic at 1.1 times working pressure

Three Piece Screwed End Ball Valve Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 7-10 Days

About Three Piece Screwed End Ball Valve

Three Piece Screwed End Ball Valve is a compact and durable plumbing equipment which is used as a flow control unit that makes it very easier to increase or decrease the water flow. It is fabricated by using stainless steel which imparts greater strength, rigidity and makes it suitable for corrosive as well as non-corrosive fluids. This valve is provided with a manually controlled lever with the help of which we can move the ball fixed within the valve body.

Three Piece Screwed End Ball Valve Specifications:

1. Pressure: High Pressure

2. Material: Stainless Steel

3. Connector Type: Screwed

4. Size: 15mm to 50mm

Three Piece Screwed End Ball Valve Features:

1. Design and Construction:

Three-piece design: The valve consists of three main parts - a body and two end caps - that are bolted together, allowing for easy maintenance, repair, or replacement of individual components without needing to remove the entire valve from the pipeline.

Screwed end connections: These valves have threaded (screwed) ends that allow for easy installation and connection to threaded pipes or fittings.

2. Ball Valve Mechanism:

a. Quarter-turn operation: Ball valves use a quarter-turn mechanism, where a 90-degree rotation of the valve handle or actuator turns the valve from fully closed to fully open position or vice versa.

b. Full bore design: When the valve is fully open, the bore (opening) through the ball is the same size as the pipeline, minimizing flow restrictions and pressure drop.

3. Flow Control:

a. Excellent shut-off capability: Ball valves provide a tight shut-off, ensuring minimal leakage when the valve is in the closed position.

b. Quick and precise flow control: The simple quarter-turn operation allows for fast response to changes in flow requirements, making them suitable for applications requiring precise control.

4. Durability and Reliability:

a. Robust materials: These valves are commonly made from materials such as stainless steel, brass, or other corrosion-resistant alloys, making them suitable for various environments and fluids.

b. Long service life: The sturdy construction and minimal moving parts contribute to the valve's longevity and reliability.

5. Versatility:

a. Wide range of applications: Three-piece screwed end ball valves are used in various industries, including oil and gas, chemical, water treatment, pharmaceuticals, and more.

b. Compatibility: They can handle a variety of fluids, from gases to liquids with different properties.

6. Easy Maintenance:

a. Component replacement: The three-piece design allows for easy disassembly, which simplifies maintenance tasks such as cleaning, inspection, and repair.

b. Seal replacement: If the valve's sealing components wear out over time, they can be replaced without removing the entire valve from the pipeline.

7. Options and Accessories:

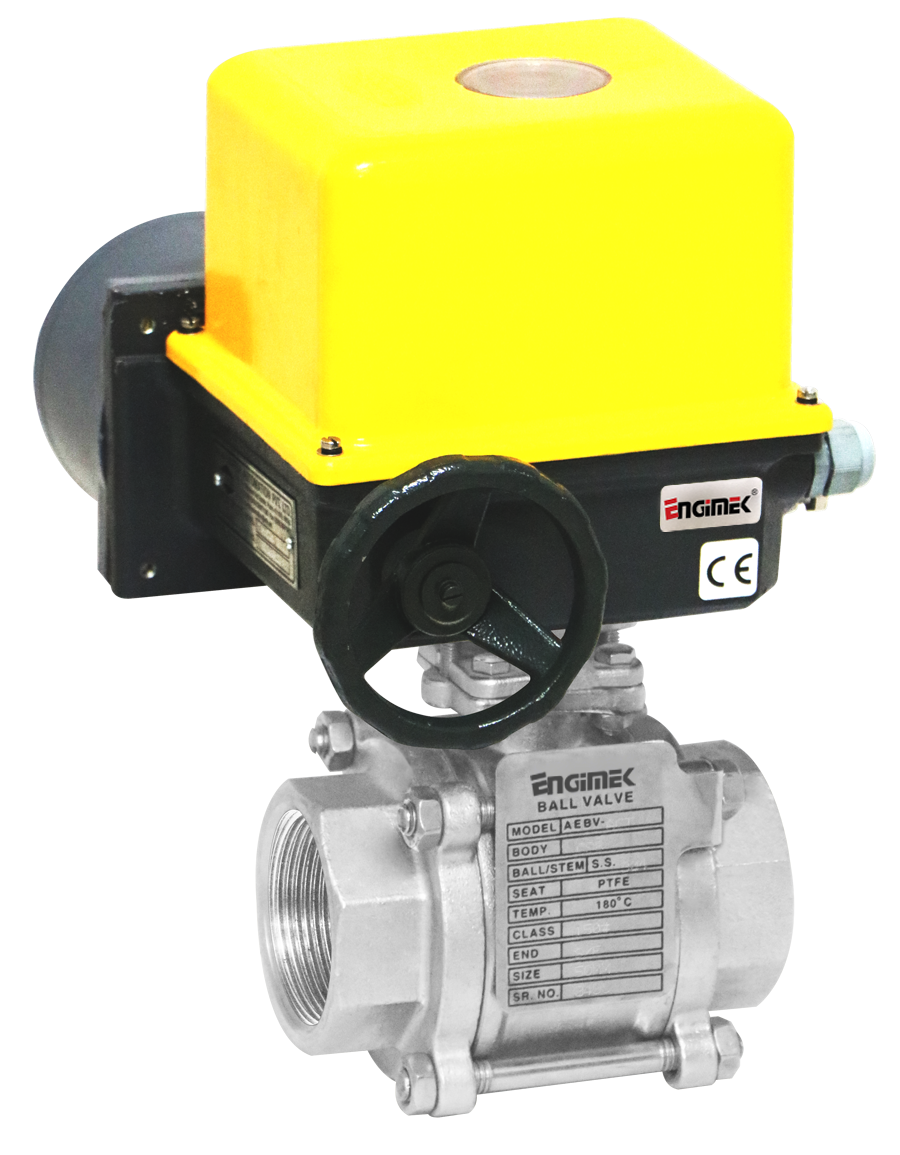

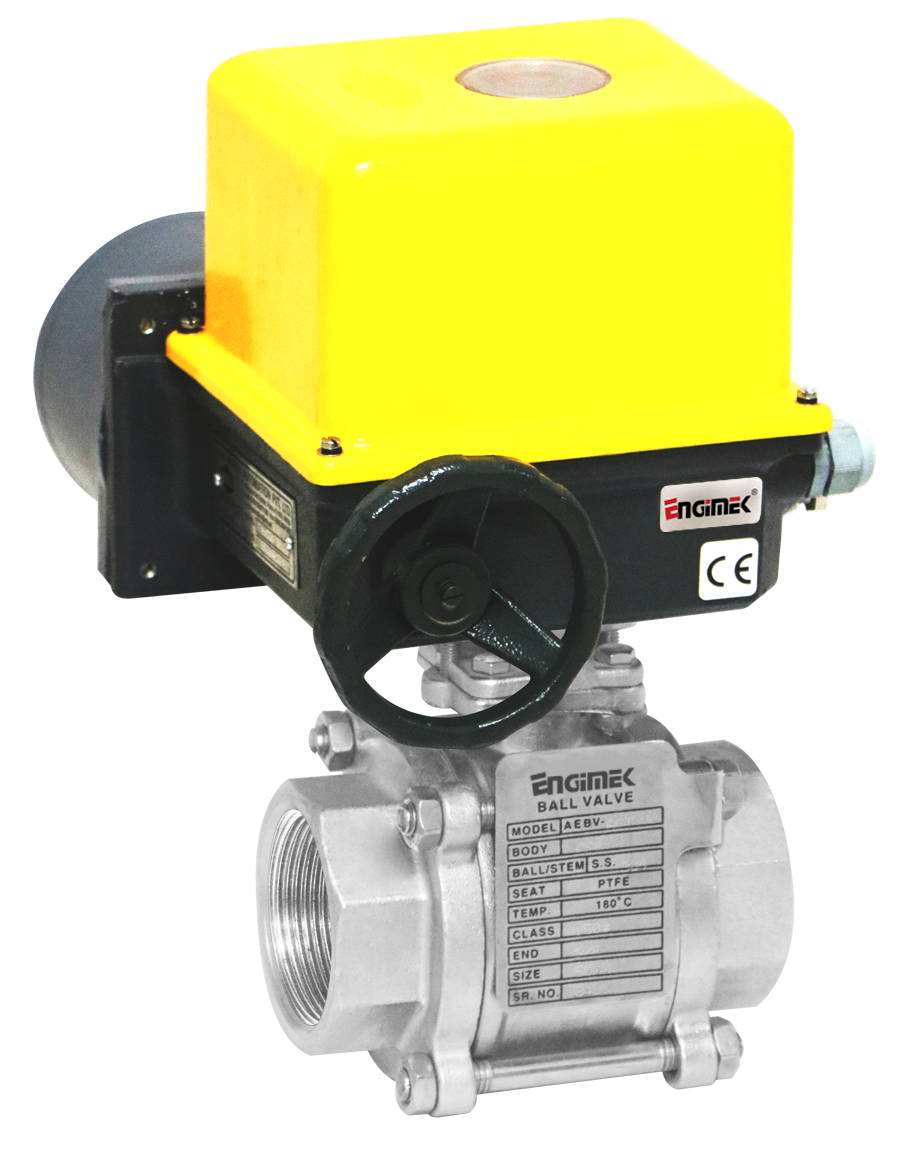

a. Actuation: Ball valves can be operated manually using a handle or automatically using pneumatic, electric, or hydraulic actuators for remote control and automation.

b. Locking devices: Some valves come with locking mechanisms to prevent unauthorized or accidental valve operation.

8. Cost-Effective Solution:

Compared to other types of valves, three-piece screwed end ball valves often offer a cost-effective solution for various applications due to their simple design and ease of maintenance.

FAQ:

Q. What is a three-piece screwed end ball valve?

Ans: A three-piece screwed end ball valve is an industrial valve designed to control the flow of fluids within pipelines. It consists of three main components that can be disassembled for easy maintenance or repair. The valve is equipped with threaded (screwed) ends for convenient installation onto threaded pipes or fittings.

Q. How does a three-piece screwed end ball valve work?

Ans: These valves use a ball with a hole through it as the controlling element. A 90-degree rotation of the valve handle or actuator turns the ball inside the valve body to either block or allow fluid flow. When the ball's hole aligns with the pipeline, flow occurs; when the ball is turned to block the hole, flow is stopped.

Q. What are the advantages of the three-piece design?

Ans: The three-piece design allows for easy maintenance, repair, or replacement of individual components without removing the entire valve from the pipeline. This reduces downtime and costs associated with maintenance activities.

Q. Where are three-piece screwed end ball valves used?

Ans: These valves are used in a wide range of industries, including oil and gas, chemical, water treatment, food processing, and more. They are suitable for applications where tight shut-off, precise flow control, and easy maintenance are required.

Q. What are the benefits of using screwed end connections?

Ans: Screwed end connections simplify installation and provide a secure, threaded attachment to pipelines or fittings without the need for welding or other complex joining methods.

Q. Can three-piece screwed end ball valves handle different types of fluids?

Ans: Yes, these valves can handle various fluids, including liquids and gases, as long as the materials of construction are compatible with the fluid properties and environmental conditions.

Q. Are there options for automation?

Ans: Yes, many three-piece screwed end ball valves can be equipped with pneumatic, electric, or hydraulic actuators for remote operation and automation. This is particularly useful in scenarios where manual operation is not practical.

Q. What maintenance is required for these valves?

Ans: Regular maintenance involves inspecting the valve for leaks, checking the operation of the handle or actuator, and ensuring that seals and gaskets are in good condition. Depending on usage, periodic lubrication and cleaning might also be necessary.

Q. Can these valves be used for throttling or flow control?

Ans: Yes, ball valves can be used for flow control, but their design is better suited for on/off applications. While they can be used for throttling, precise control might be more challenging compared to specialized control valves.

Q. Are these valves resistant to corrosive environments?

Ans: Many three-piece screwed end ball valves are made from materials such as stainless steel or corrosion-resistant alloys, which makes them suitable for use in corrosive environments.

Q. Can I replace seals without removing the valve from the pipeline?

Ans: Yes, the three-piece design allows for disassembling the valve to replace seals or other components without needing to remove the entire valve from the pipeline.

Q. Are there limitations to using these valves?

Ans: While these valves offer numerous advantages, they might not be the best choice for applications requiring fine or precise flow control due to their quarter-turn operation. Additionally, they might have limitations in high-pressure or high-temperature applications.

Reliable Flow Control for Industrial Needs

This valve is engineered for demanding industrial environments, providing superior performance with its robust three-piece construction. The hydrostatic body and ball test ensure pressure safety, while the polished and machined finish enhances durability. Whether handling chemicals, petrochemicals, or steam, the valve's bubble-tight closure and blowout-proof stem deliver operational confidence.

Versatile Connection and Safety Features

Designed for flexibility, the valve offers BSP or NPT screwed end connections as per global standards (IS/ISO/DIN). It also features an optional ISO 5211 mounting pad for actuators, a secure locking mechanism, antistatic device, and fire-safe design for added safety and adaptability in various industrial processes.

FAQ's of Three Piece Screwed End Ball Valve:

Q: How does the three-piece screwed end ball valve ensure zero leakage?

A: The valve utilizes a bubble-tight sealing mechanism with a PTFE/Teflon seat, which is tested at 1.5 times the working pressure for the body and 1.1 times for the ball, ensuring reliable shutoff and complete zero leakage in service.Q: What are the typical applications for this valve in an industrial setting?

A: It is widely suited for chemical, petrochemical, process industries, and water treatment plants, handling media such as water, oil, gas, acid, and steam at temperatures ranging from -20C to +200C and pressures up to PN63/1000 PSI.Q: When should I use the optional fire safe and antistatic features?

A: These optional features are recommended in environments where fire risks or static electricity may compromise safety, such as in chemical processing or petrochemical plants, providing an additional layer of safety and regulatory compliance.Q: Where can the three-piece screwed end ball valve be installed?

A: It can be installed in any pipeline requiring reliable isolation, especially where threaded (BSP/NPT) connections are needed and frequent maintenance is anticipated due to its easily removable three-piece structure.Q: What is the process for testing this valve before delivery?

A: Each valve undergoes hydrostatic testing: the body is tested at 1.5 times its working pressure and the ball at 1.1 times, conforming to strict international standards to ensure safety and performance before shipment.Q: How does the locking arrangement enhance valve usage?

A: The locking feature provides secure operation by preventing unauthorized or accidental manipulation of the valve, which is particularly useful in critical applications or where safety protocols are essential.Q: What are the main benefits of choosing a stainless steel handle with a PVC sleeve?

A: This handle offers superior corrosion resistance and durability, while the PVC sleeve ensures comfortable and safe manual operation, especially in extreme temperature or industrial conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pneumatic Ball Valve Category

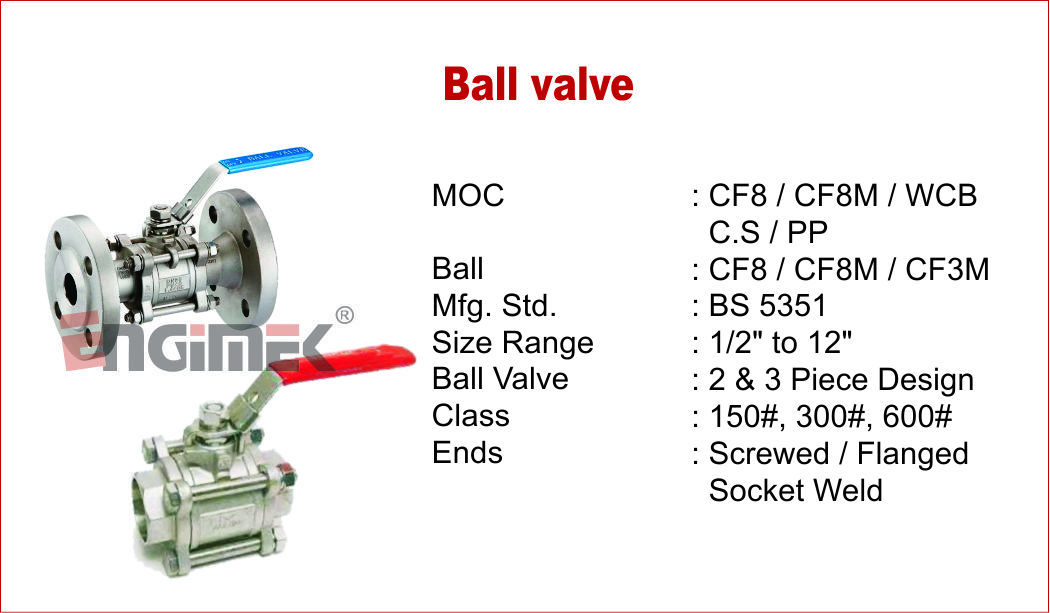

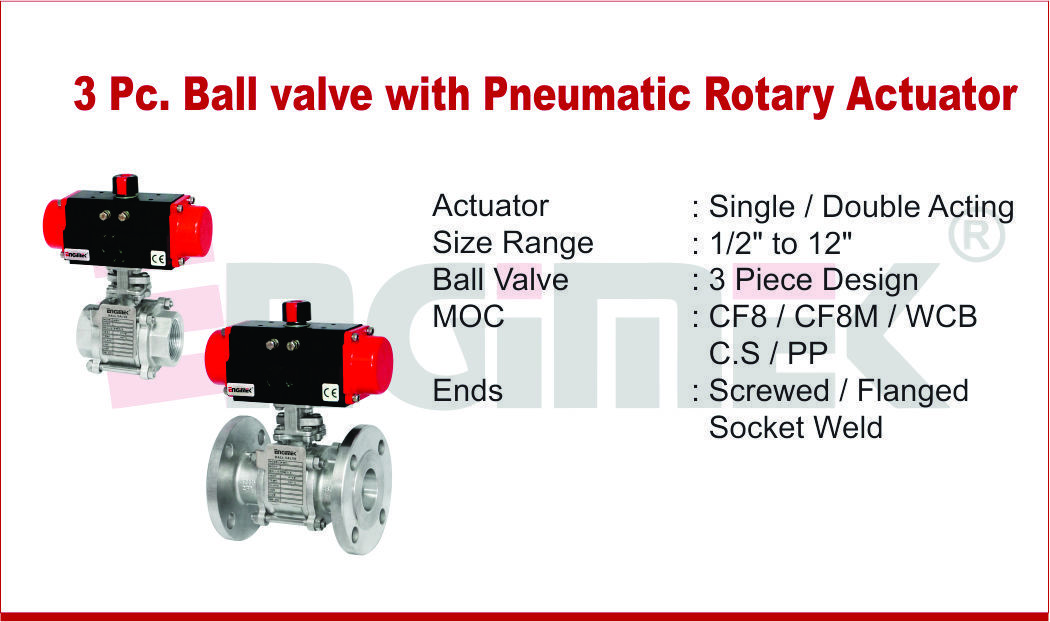

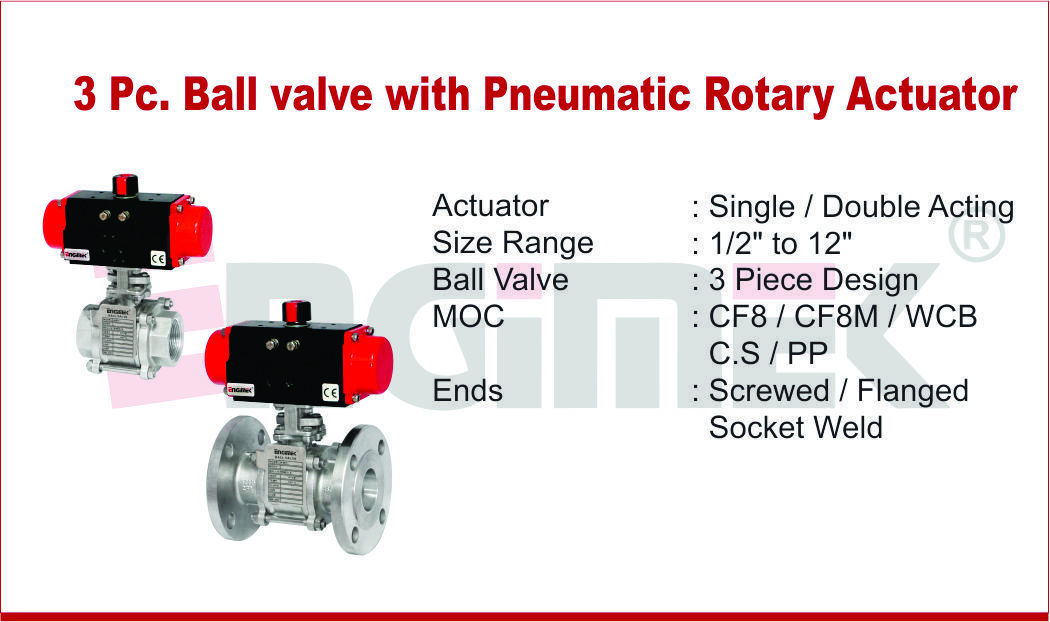

3 Pieces Ball Valve With Pneumatic Rotary Actuator

Price 3000-10000 INR / Piece

Minimum Order Quantity : 01 Piece

Structure : Ball

Material : Stainless Steel

Connection : New

Size : 50 to 600 mm

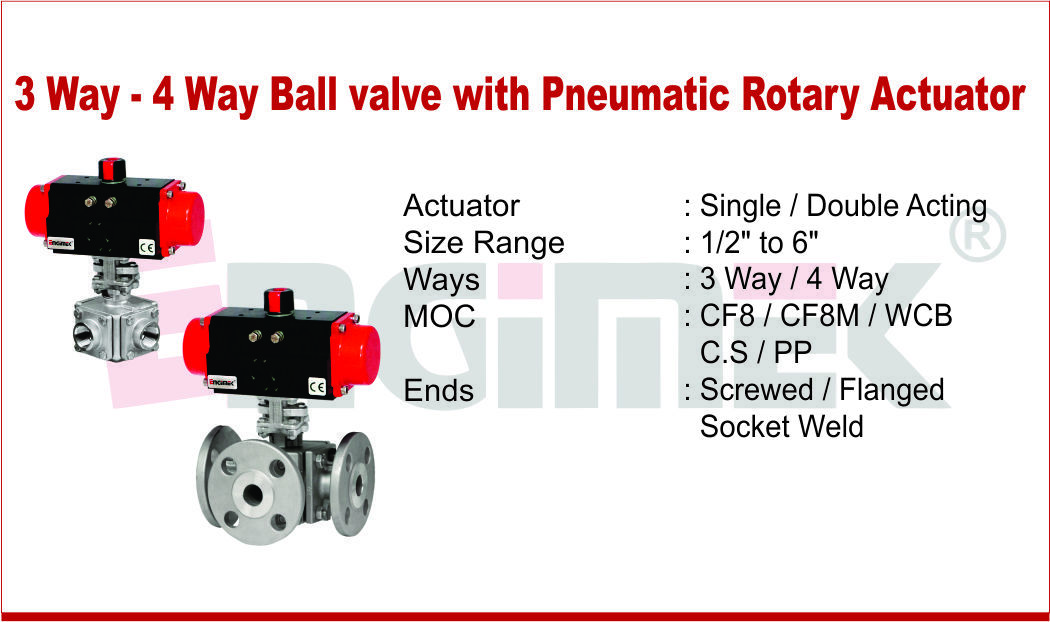

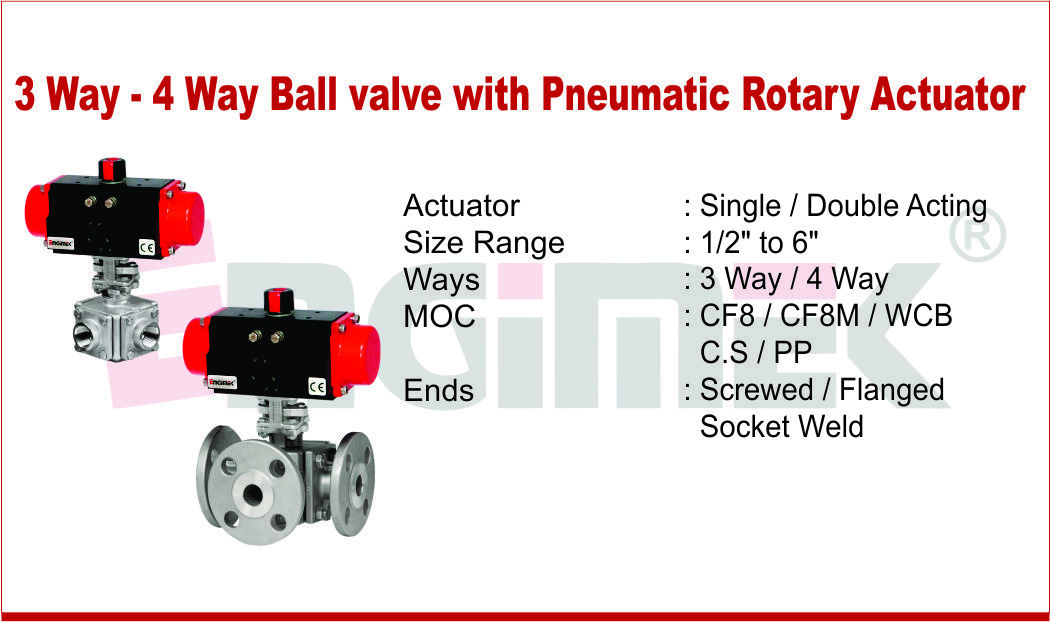

3 Way Ball Valve With Pneumatic Rotary Actuator

Price 10000 INR / Piece

Minimum Order Quantity : 01 Piece

Structure : Ball

Material : Stainless Steel

Connection : New

Size : 50 to 600 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free