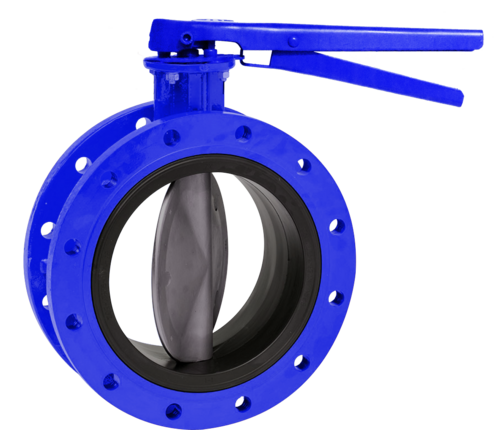

Gear Operated Triple Offset Butterfly Valve

Gear Operated Triple Offset Butterfly Valve Specification

- Connection

- Flanged Ends as per ASME/ANSI/DIN/BS Standards

- Valve Type

- Triple Offset Butterfly Valve

- Material

- Carbon Steel / Stainless Steel / Alloy Steel (Body & Disc)

- Power Source

- Manual (Gear Operated)

- Pressure

- PN 10 / PN 16 / PN 25 / ANSI 150# / ANSI 300#

- Media

- Water, Oil, Gas, Steam & Chemicals

- Working Temperature

- Up to 425C (Depending on Material)

- Port Size

- 2 to 48 (50mm to 1200mm)

- Shape

- Wafer / Lug / Double Flanged

- Leakage Class

- API 598 / EN 12266-1

- Operation

- Handwheel with Gearbox

- Face to Face Dimensions

- As per API 609 / EN 558

- Disc Design

- Offset Triple Eccentric

- End Connection Standards

- ASME, DIN, BS, EN, JIS

- Coating

- Epoxy Coated / Painted

- Application

- Power, Oil & Gas, Chemical, Water Treatment, HVAC, Marine

- Seat Material

- Metal Seated / Soft Seated (PTFE, RPTFE, etc.)

- Body Design

- One Piece / Two Piece

Gear Operated Triple Offset Butterfly Valve Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 1 Days

About Gear Operated Triple Offset Butterfly Valve

This Gear Operated Triple Offset Butterfly Valve is made with the highest engineering quality and is intended to easily handle the most demanding industrial applications. Use the gear-operated mechanism to unleash the power of smooth operation, allowing you to precisely change the valve's position for the best fluid flow management. This Gear Operated Triple Offset Butterfly Valve's triple offset design provides a bubble-tight shut-off, minimizing leakage to the barest minimum whether you are working with liquids, gases, or slurries.

Benefits:

- Precision-engineered parts in the Gear Operated Triple Offset Butterfly Valve guarantee smooth operation and little leakage.

- Due to its triple offset design, the sealing surfaces endure less wear and tear while providing bubble-tight sealing.

- The valve, made of durable materials, provides enduring performance even in harsh industrial situations.

- This valve allows for precise flow modulation through smooth and controlled actuation.

- It is appropriate for use in high-temperature fluid systems since it is made to tolerate high temperatures.

Engipro Solutions LLP is one of the leading manufacturers and suppliers of heavy duty Gear Operated Triple Offset Butterfly Valve that is designed and developed by our team of skilled professionals using advanced production technologies. It is made up of heavy duty engineering materials that offers high rigidity and robustness which leads to longer service life. The offered valve is available in various sizes as per the flow systems in which it is going to be installed. Buy from us this industrial class valve as per your demands within the price range of

10000 to 100000 INR per piece.

Let's break down the key terms to understand its features and functionality:

Benefits of a Gear Operated Triple Offset Butterfly Valve:

Precision Control and Durability

Triple offset disc geometry ensures outstanding shutoff and minimizes seat wear, even under harsh operating conditions. The metal or soft seat options cater to diverse media, including steam, chemicals, oil, and gas. Robust materials and reliable epoxy-coated or painted surfaces add to the valve's lasting performance, making it a preferred choice in mission-critical sectors.

Versatile and Standards-Compliant Design

With choices in body/port size (2" to 48", 50mm to 1200mm), end connections, and international face-to-face standards (API 609/EN 558), these butterfly valves integrate smoothly into global pipelines. Options of one-piece or two-piece body designs, as well as wafer, lug, and double flanged shapes, provide installation flexibility for distributors and suppliers worldwide.

FAQ's of Gear Operated Triple Offset Butterfly Valve:

Q: How does a gear operated triple offset butterfly valve provide reliable shutoff in industrial applications?

A: The triple eccentric disc design eliminates friction during opening and closing, enabling a tight, bubble-proof seal. This architecture, combined with metal or soft seat options, ensures consistent performance and minimal wear, making it highly suitable for critical flows in industries like power, oil & gas, and chemical processing.Q: What are the main benefits of choosing between metal seated and soft seated valves?

A: Metal seated valves withstand extreme temperatures (up to 425C) and abrasive media, while soft seated (PTFE, RPTFE) options offer excellent chemical resistance and lower torque operation. The choice allows customization for specific media, operating environments, and leakage class requirements.Q: Where are these triple offset butterfly valves commonly installed?

A: These valves are widely used in power generation, oil & gas, chemical plants, water and wastewater treatment, marine, and HVAC systems. Their robust design and versatile connection standards (ASME, DIN, BS, EN, JIS) enable integration into global industrial projects.Q: When should I select a double flanged versus wafer or lug type body design?

A: Double flanged designs are favored for high-pressure or severe service requiring secure mounting between flanges. Wafer and lug types offer space-saving installation and are suitable for less demanding applications, providing options based on installation constraints and pressure ratings.Q: What is the process of operating this valve using the gear mechanism?

A: Operation involves manually turning the handwheel, which, through the gearbox, multiplies force to smoothly and precisely rotate the disc. The gearing ensures easy handling regardless of valve size, enabling fine control even under high pressure.Q: Can this valve handle a variety of media and pressure ranges?

A: Yes, designed with carbon steel, stainless steel, or alloy steel bodies and discs, these valves manage water, gas, oil, steam, and various chemicals across pressure ratings from PN10 to ANSI 300#, adapting to a wide spectrum of industrial demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Butterfly Valve Category

Motorized Butterfly Valve

Price 12000.00 INR / Unit

Minimum Order Quantity : 15 Pieces

Material : Stainless Steel

Product Type : MOTORIZED BUTTERFLY VALVE

Size : 3

Double Flange Butterfly Valve

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Valve Type : Wafer Type Butterfly Valve

Material : Other, CI, CS, SS304, SS316

Product Type : Double Flange Butterfly Valve

Size : 148 Inch

Pneumatic Rotary Actuator Operated Butterfly Valve

Price 16000 INR / Piece

Minimum Order Quantity : 01 Piece

Valve Type : Wafer Type Butterfly Valve

Material : Stainless Steel

Product Type : Valve

Size : 1.1/2" to 48"

Stainless Steel Offset Disc Butterfly Valve

Minimum Order Quantity : 1 , , Piece

Valve Type : Other, Butterfly Valve

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free