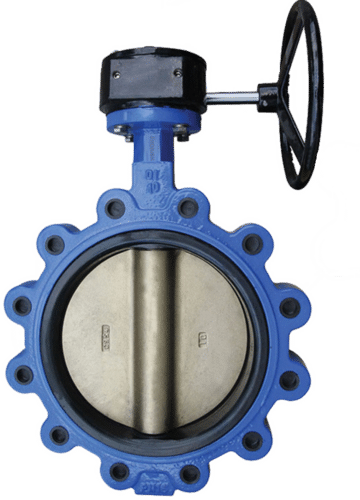

About Pneumatic Rotary Actuator Operated Butterfly Valve

We are engaged in offering an excellent quality assortment of Butterfly Valve With Pneumatic Rotary Actuator. Designed and manufactured by using the finest quality raw materials and cutting-edge techniques, our range of valve fulfill the set norms of quality. Suitably applicable in petrochemicals, pharmaceuticals, chemicals and food processing industries, this valve is available in different sizes and other specifications as per the demanding needs of the clients. Clients can avail this product at highly competitive rates from us.

Butterfly Valve With Pneumatic Rotary Actuator Features:

1. Pneumatic Actuation: Pneumatic actuators use compressed air to operate the valve, making them suitable for applications where electricity might not be ideal or available. The use of air pressure allows for fast and precise valve control.

2. Compact Design: Butterfly valves, in general, have a compact design that requires less space compared to other types of valves. The addition of a pneumatic actuator further enhances this compactness, making them suitable for installations where space is limited.

3. Quick Operation: Pneumatic actuators can provide quick valve operation, allowing for rapid response to control signals. This is especially important in applications where fast flow shut-off or modulation is required.

4. Fail-Safe Options: Butterfly valves with pneumatic actuators often have fail-safe options. In case of power or air supply failure, these valves can be designed to automatically close or open, depending on the process requirements. This feature helps prevent accidents or process disruptions.

5. Position Control: Pneumatic rotary actuators allow for precise positioning of the valve disc. This is essential for accurate flow control and modulation, allowing the valve to be set at specific angles to achieve the desired flow rate.

6. Remote Control: Pneumatic butterfly valves can be controlled remotely using control systems or distributed control systems (DCS). This is particularly useful in industrial settings where manual valve operation is not feasible or convenient.

7. Corrosion Resistance: Butterfly valves can be manufactured from various materials such as stainless steel, cast iron, or exotic alloys to withstand corrosive environments. The combination of suitable materials and the actuator's external positioning helps protect the actuator from the process fluid.

8. Maintenance: Pneumatic actuators are generally easy to maintain and repair. Regular maintenance can extend the life of the actuator and ensure its optimal performance.

9. Modularity: Butterfly valves with pneumatic actuators often come in modular designs. This means that the actuator can be detached and replaced without needing to replace the entire valve assembly, reducing downtime and maintenance costs.

10. Automation Integration: These valves can be integrated into larger automation and control systems, allowing for seamless communication and coordination with other components of the industrial process.

11. Wide Range of Applications: Butterfly valves with pneumatic rotary actuators find applications in various industries, including water treatment, chemical processing, oil and gas, HVAC systems, and more, due to their versatility and reliable performance.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free